Pipeline Integrity Management

Ensuring the integrity of the pipeline systems we operate is a top priority to help us provide safe, reliable service to our customers. Pipeline integrity management is a process for assessing and mitigating pipeline risks to reduce the likelihood and consequences of incidents. New Mexico Gas Company’s Integrity Management Program (IMP) is an integral part of achieving this goal and complying with laws and regulations. We have implemented IMP for distribution and transmission facilities.

Steps in the Distribution Integrity Management Program (DIMP) include:

- Threat Identification and Risk Analysis -- We analyze pipeline segments to identify threats to the pipeline as well as the public safety and environmental consequences of a pipeline failure to assess the total risk.

- Risk Mitigation -- We develop programs or activities to address the risk.

- Performance Measurement & Effectiveness Evaluation -- We evaluate the performance and effectiveness of programs and activities to determine if changes are warranted.

- Periodic Evaluation -- We evaluate the Integrity Management Program for areas of success. We identify areas on our distribution system where improvements can be made. And we incorporate these improvements into ongoing safety initiatives.

Steps in the Transmission Integrity Management Program (TIMP) include:

- High Consequence Area Identification -- Locations along the pipeline system meeting the criteria for High Consequence Areas (HCAs) are identified. Generally, these are high population density areas, difficult to evacuate facilities, such as hospitals or schools, and locations where people gather, such as churches, office buildings or ball fields.

- Threat identification and Risk Analysis - We analyze individual pipeline segments to identify threats to the pipeline as well as the public safety and environmental consequences of a pipeline failure to assess the total risk.

- Integrity assessment - The pipe segments are assessed according to the schedule and methods identified in the Baseline Assessment Plan. There are three primary assessment methods:

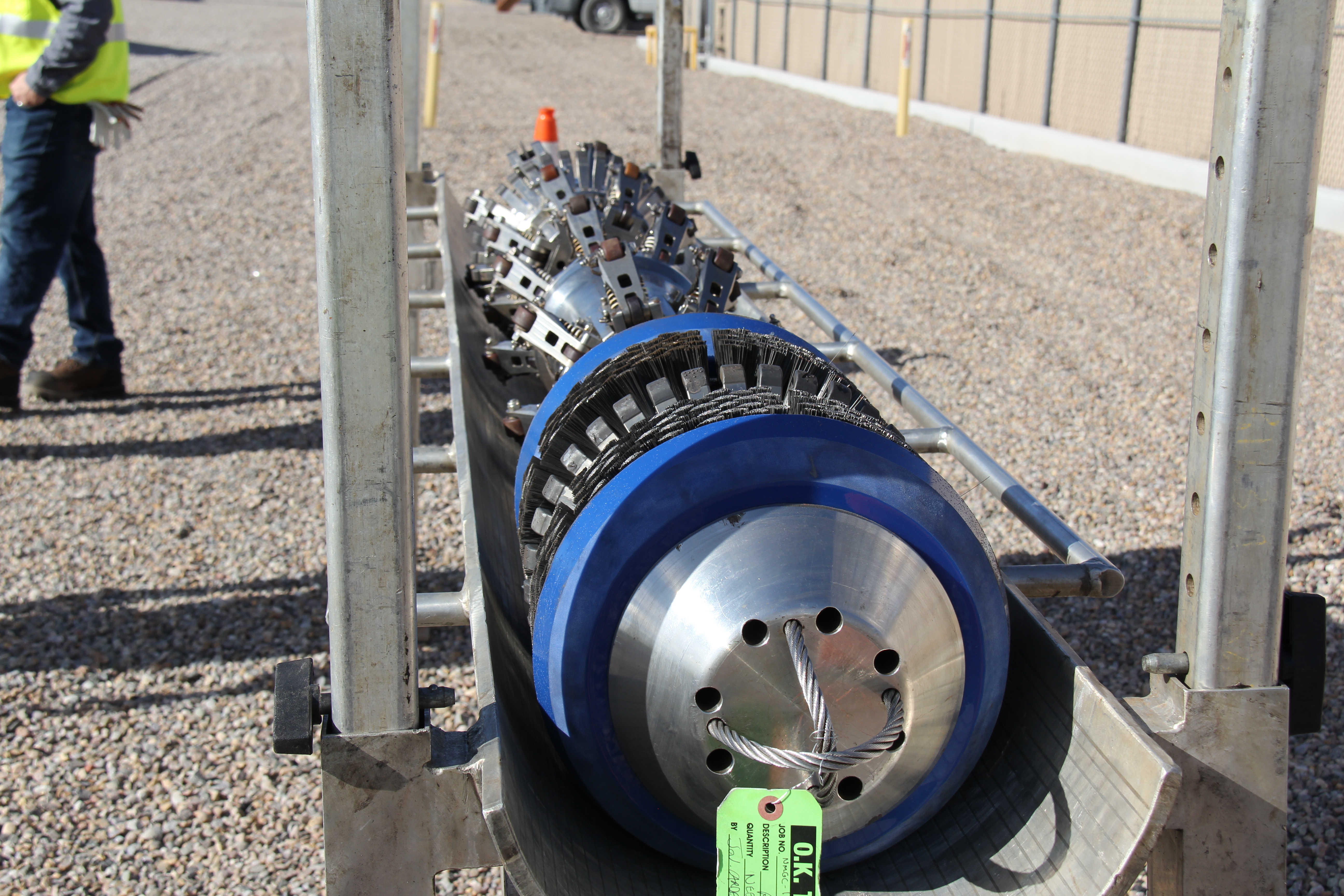

- Inline inspection - an inspection tool, often called a "smart pig," is run through the pipeline to evaluate the pipe condition.

- Direct Assessment - a structured, multi-step evaluation is conducted to identify potential problem areas. Pipe at these locations is excavated and examined.

- Pressure test - the pipe is pressured above its normal operating limit to test the strength of the pipe. Water is usually used to pressure the pipe during the test.

- Remediation - We investigate and repair issues identified during the integrity assessment step to ensure continued safe operations.

- Preventive and mitigating measures - Along with performing the integrity assessments on pipe segments, the process calls for implementing additional measures to prevent or mitigate problems before they occur.

- Stand-By Excavation Monitor is required when an excavator is digging in the Right of Way of transmission, high-pressure and large diameter pipeline.

- Remote Shut-Off Valve Installation.

- Extra patrols along the pipeline.

- Continual evaluation and assessment - A continuing plan to evaluate the integrity of the pipeline after completing the baseline assessment is also part of the process. The ongoing plan includes reviewing updated information about the pipe, analyzing risk and performing regular reassessments.

- Performance Measurement & Effectiveness Evaluation -- We evaluate the performance and effectiveness of programs and activities to determine if changes are warranted.